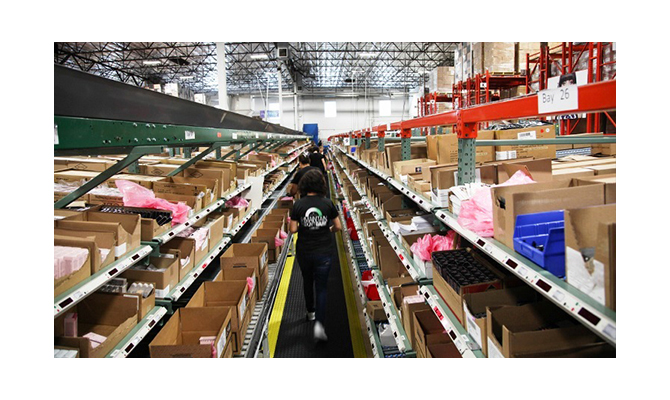

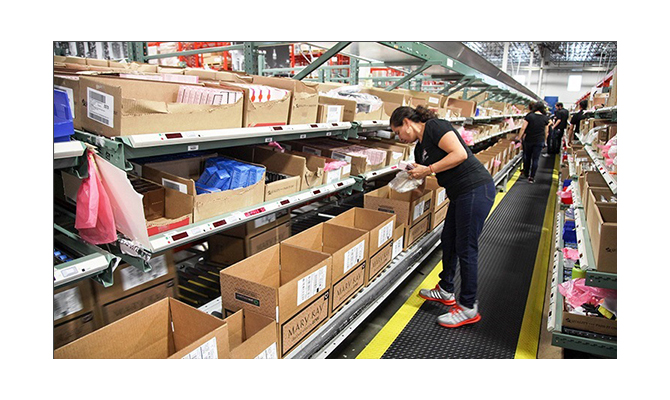

Pick To Light

There is a version of Put-to-Light sometimes called Put-to-Store or Pack-to-Light which is ideal for retail store replenishment order fulfillment where a percentage of full cases are broken down into smaller quantities. Pick to light is order-fulfillment technology that employs alphanumeric displays and buttons at storage locations to guide the manual "picking" and recording of items for shipment. This system enables the staff to recognize the exact number and location of goods very quickly (without any familiarity with goods through lights and LED Marker). In this technology, picking and packing the order is done through reciting the attached barcode on transmission boxes and activating LED marker. Then, operator loads the recalled goods and pushes "Ok" Switch, the statistics of stock will then decrease and this changes is set in WMS software.

Benefits of Pick to Light

- Increased Productivity

- Improved Order Accuracy

- Lower Labor Costs

- Paperless

- Highly Efficient